2019 was a big year for me.

Cold plasma, or non-thermal plasma (NP), is commonly used for surface treatments. NP acts as an antimicrobial tool, sterilizing medical instruments (without using a needle), as well as skin and teeth. in 2019 I learned about plasma needles from The Thought Emporium’s YouTube video here.

Several months later (now taking classes in lockdown). I had a conversation with my electromagnetics professor regarding research in treating plant seeds with cold plasma to increase their germination rate.

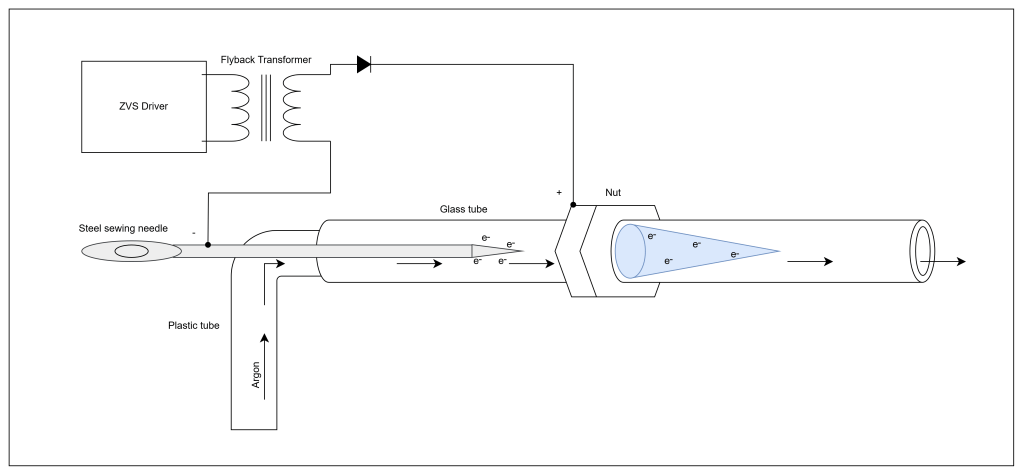

Components:

- HV Power Supply

- Argon Gas Tank (I could only afford a small 40cu/ft).

- Current Viewing Resistor (optional)

- Stainless Steel (BBQ skewer) Cathode

- Copper wire Anode (one loop)

- Quartz glass tube

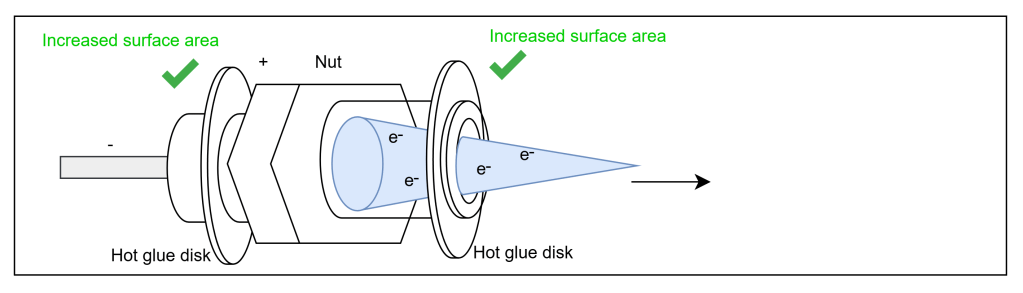

- Hot glue disks (for creepage protection)

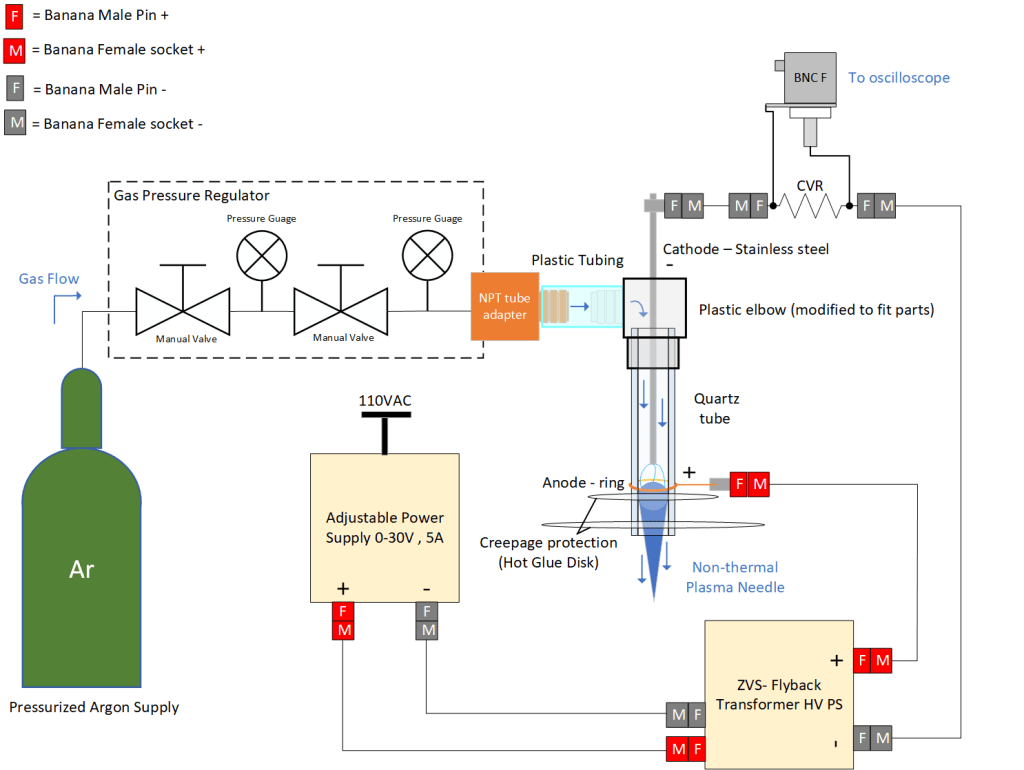

Schematic:

Power Supply:

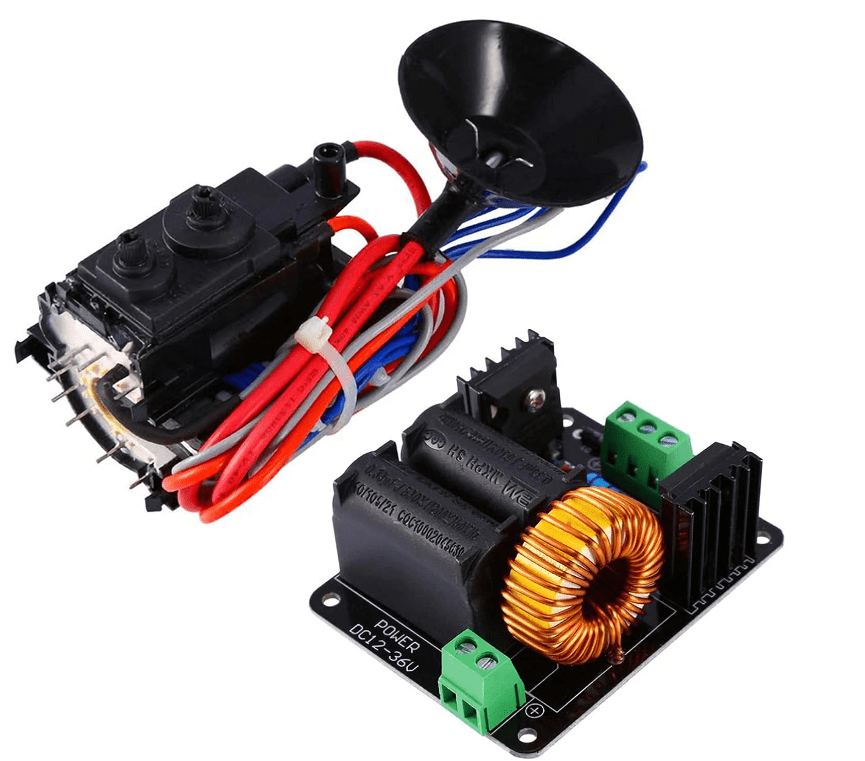

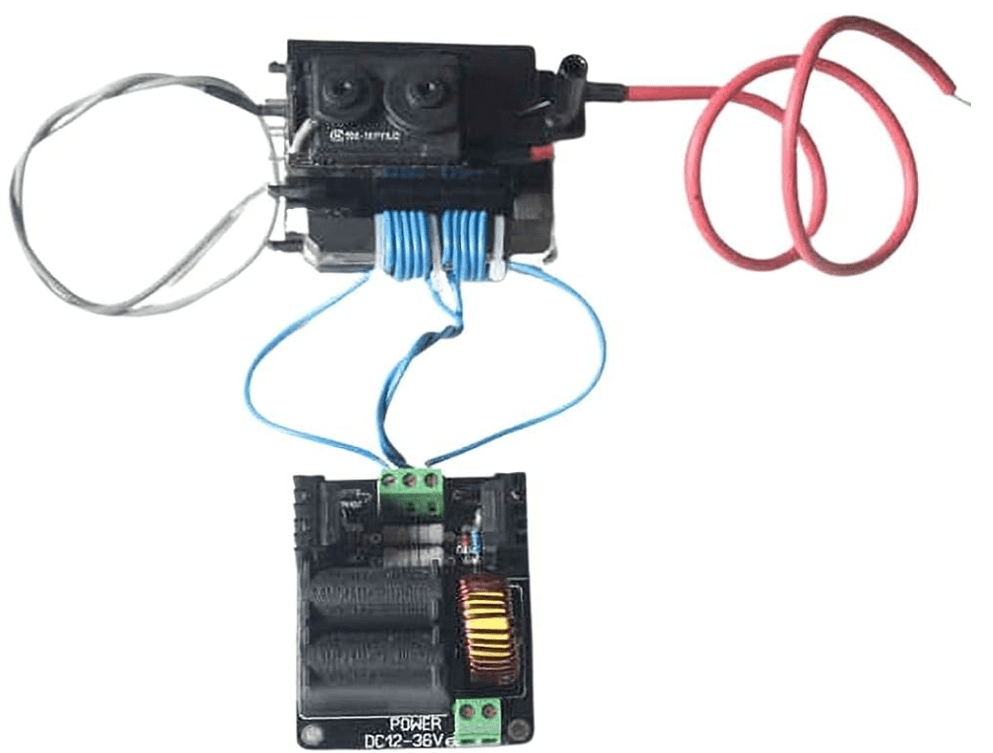

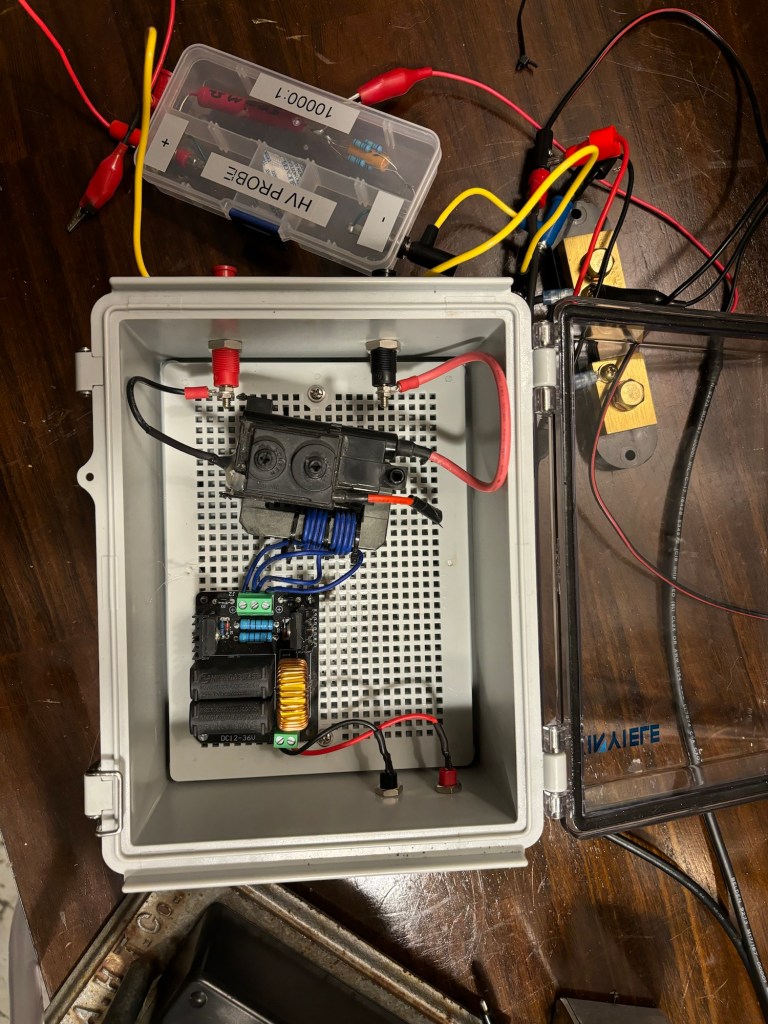

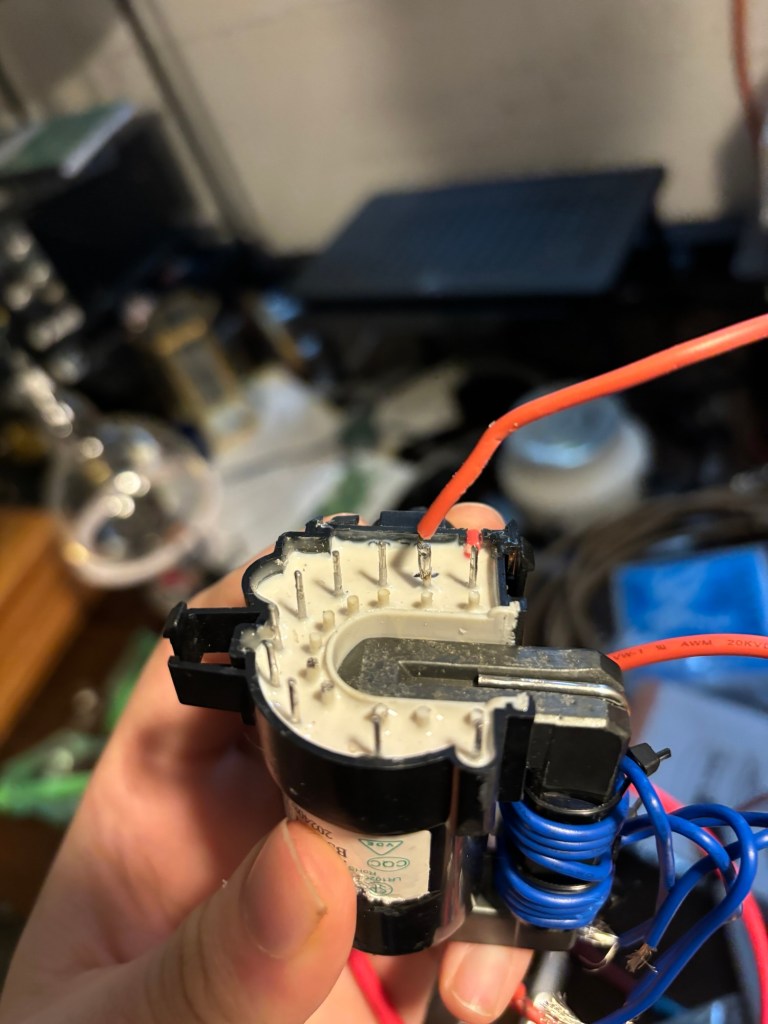

I bought a ZVS Driver and Flyback transformer off Amazon (Link here):

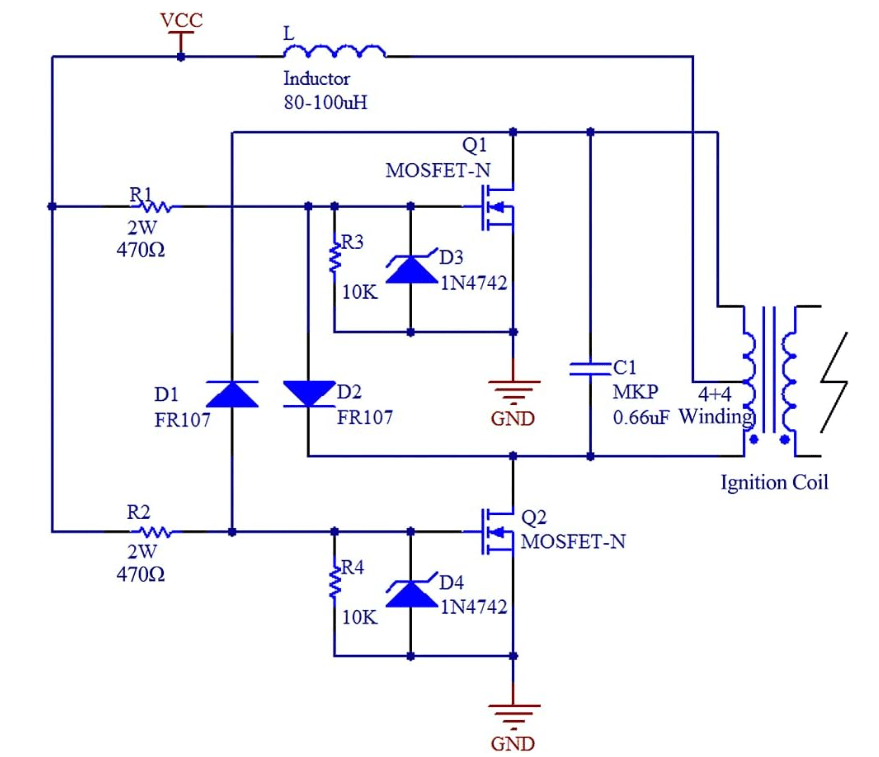

Here is the provided schematic for how the ZVS and Flyback are wired together:

Ionization Test:

The following video shows the argon plasma accelerating out past the anode.

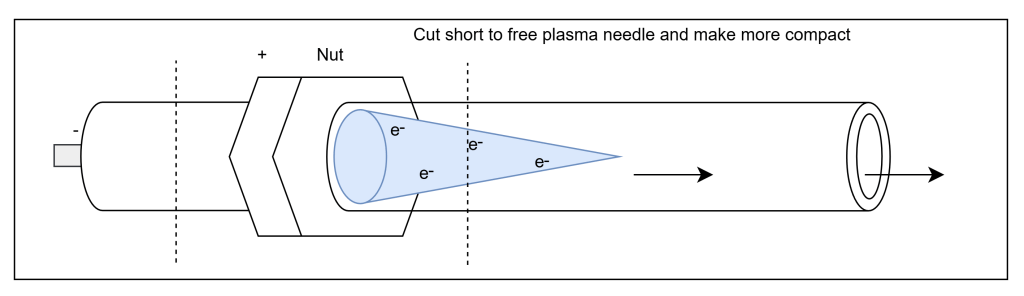

I then cut the glass shorter to allow for the plasma to exit into the open air. Technically it worked…

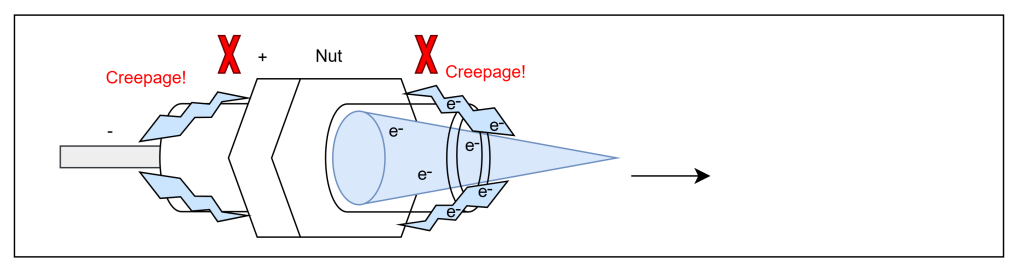

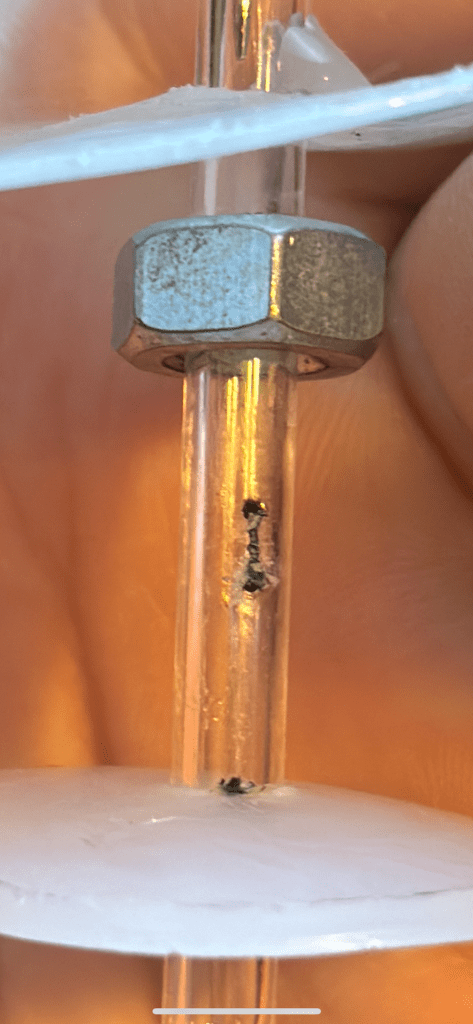

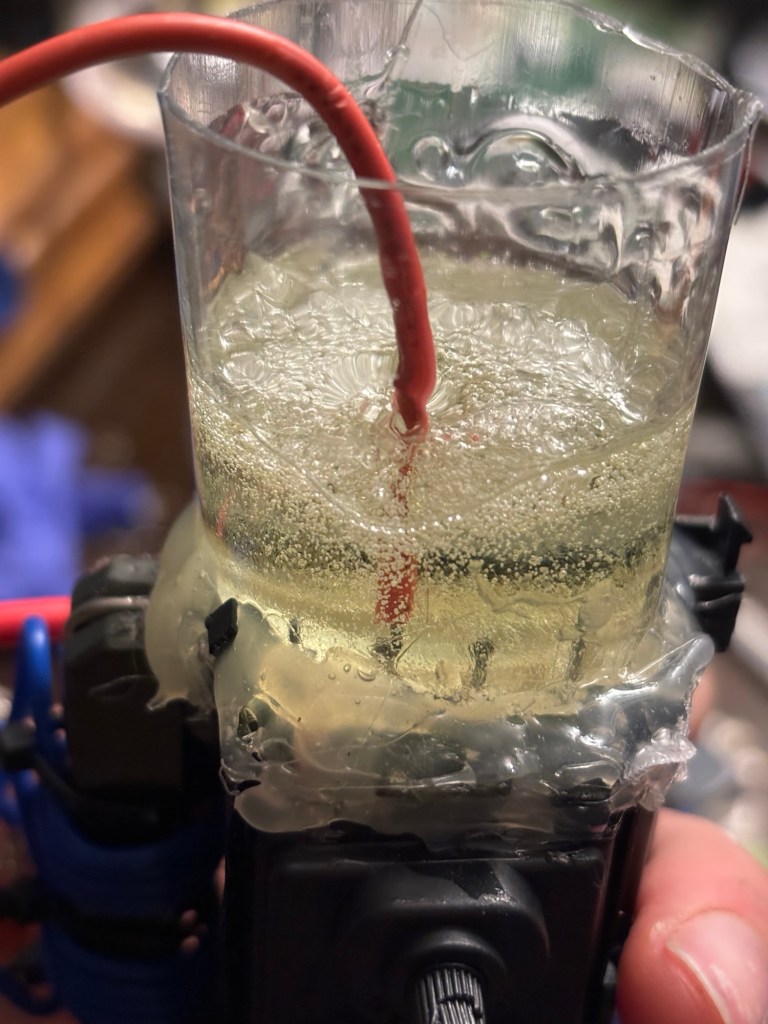

However, there was creepage. Sparks would travel across the surface of the glass tube from the cathode (the needle) to the anode (the nut).

in the video you can see a rubber stopper failing at protecting against creepage due to poor insulative contact with the glass tube. Electrons would just move though the tiny holes between the rubber and the outside of the glass tube. There’s also some creepage from the back of the glass tube.

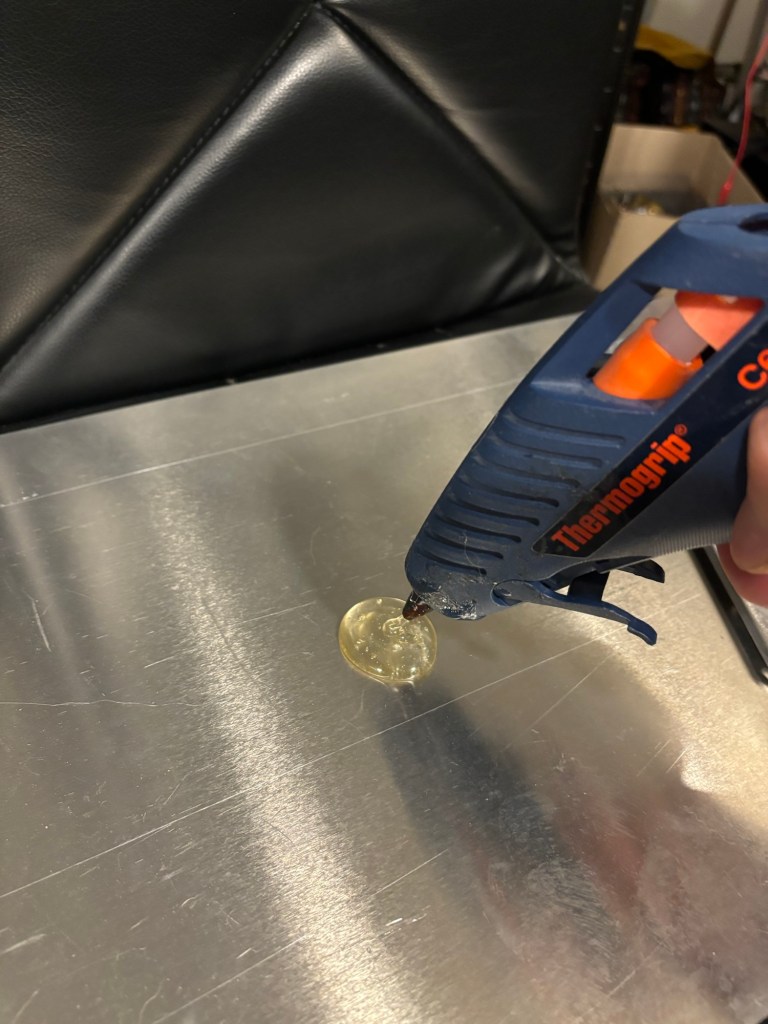

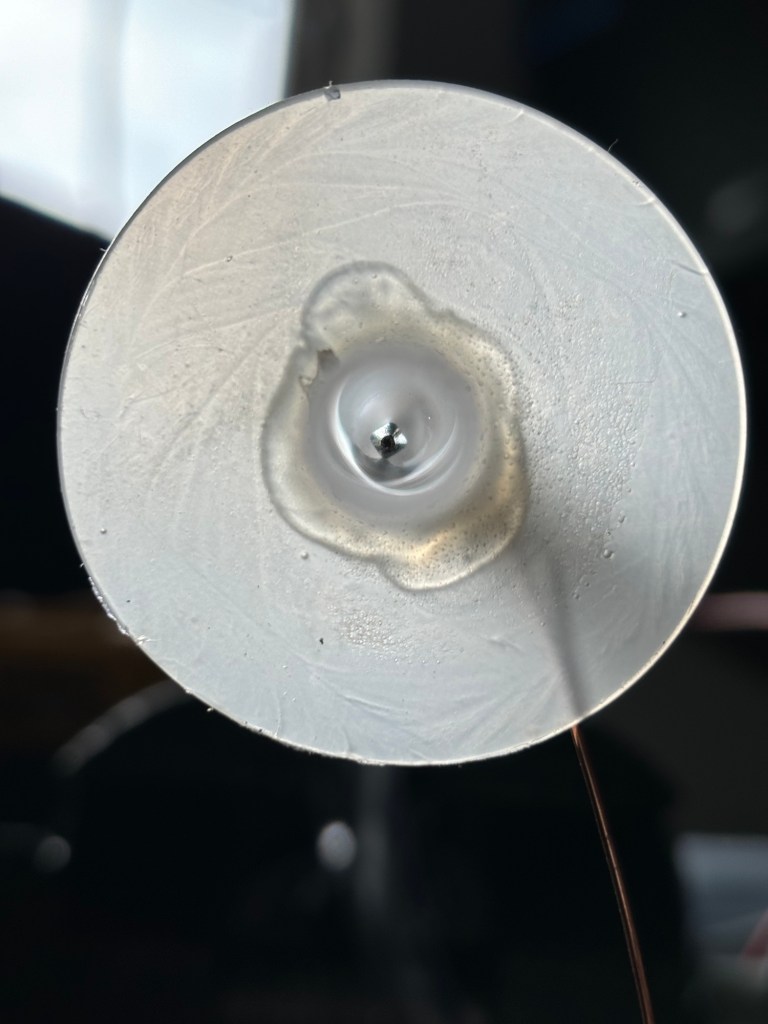

I found out a quick DIY way to increase creepage distance is by making disks made from hot glue.

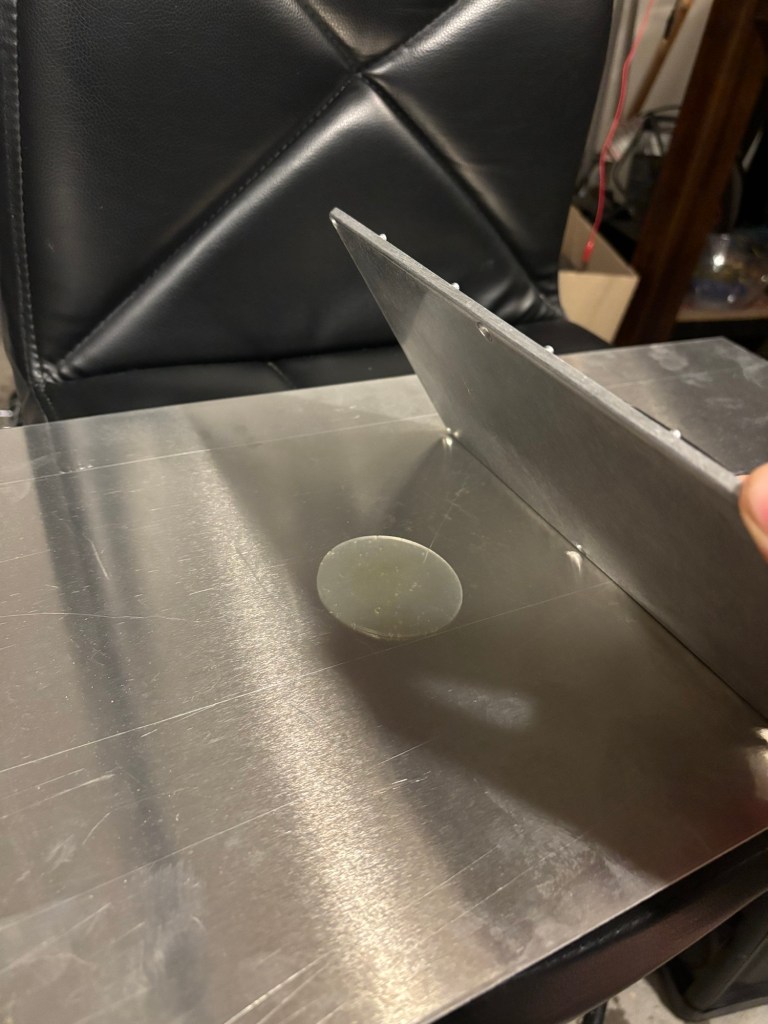

Extrude a dollop of hot glue onto a non-porous sheet (I used aluminum metal)

Quickly place another flat and non-porous sheet onto the dollop.

After a minute, remove the top sheet.

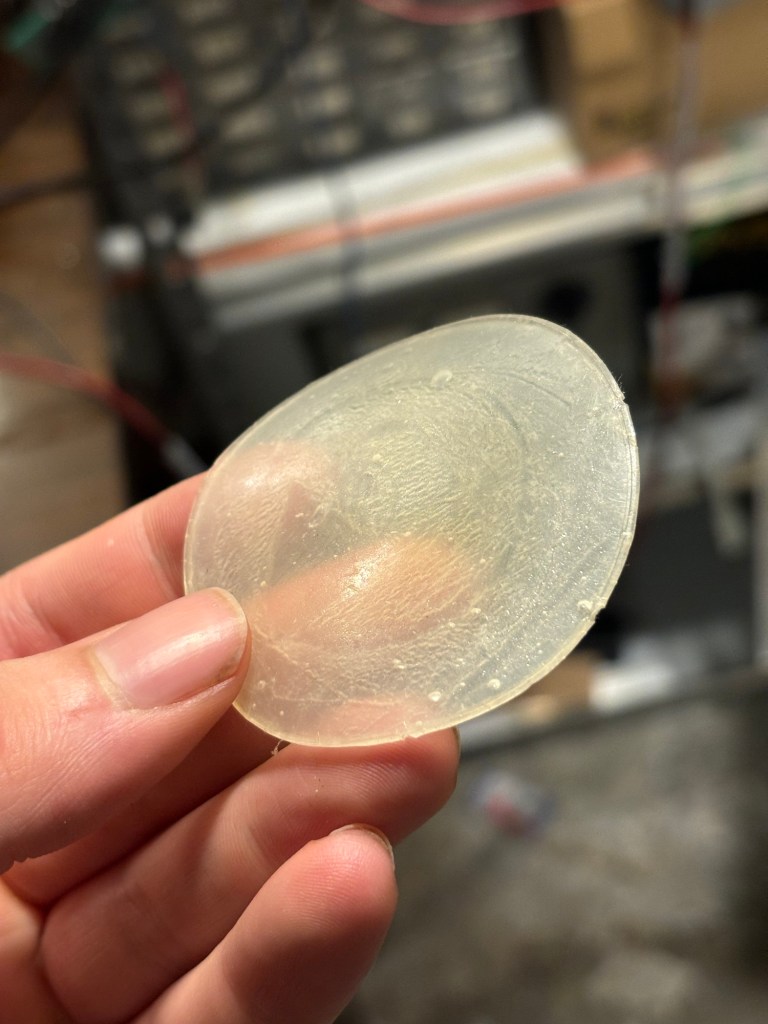

Peel off the hot glue disk. I stabbed a hole slightly smaller than the glass tube. I then threaded the tubing though the disk.

I pushed two disks on each side of the cathode to prevent creepage from the cathode feedthrough or the end of the tube. It actually worked perfectly as shown in the video below:

I exposed a match head to the plasma to demonstrate that the plasma is at least less than 148.8°C (300°F).

I can tell you that I did touch the plasma “needle”. It was room temperature and I could feel a slight electrical tingling on the tip of my finger from the carried charge. (Don’t try this yourself).

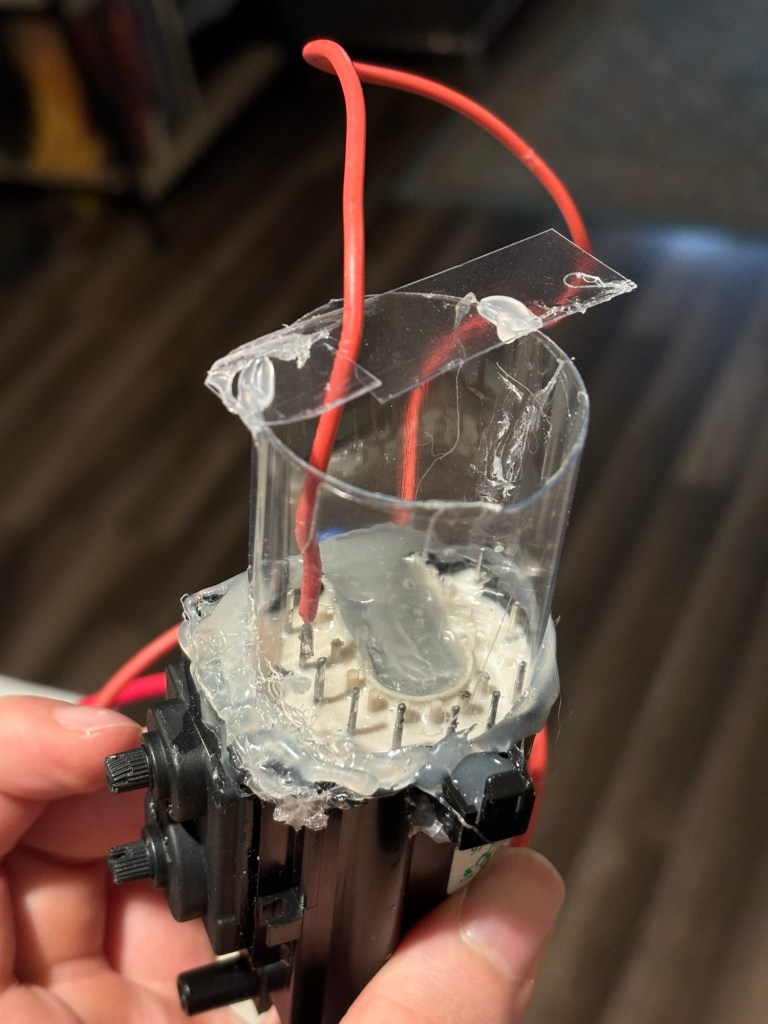

Power Supply Box

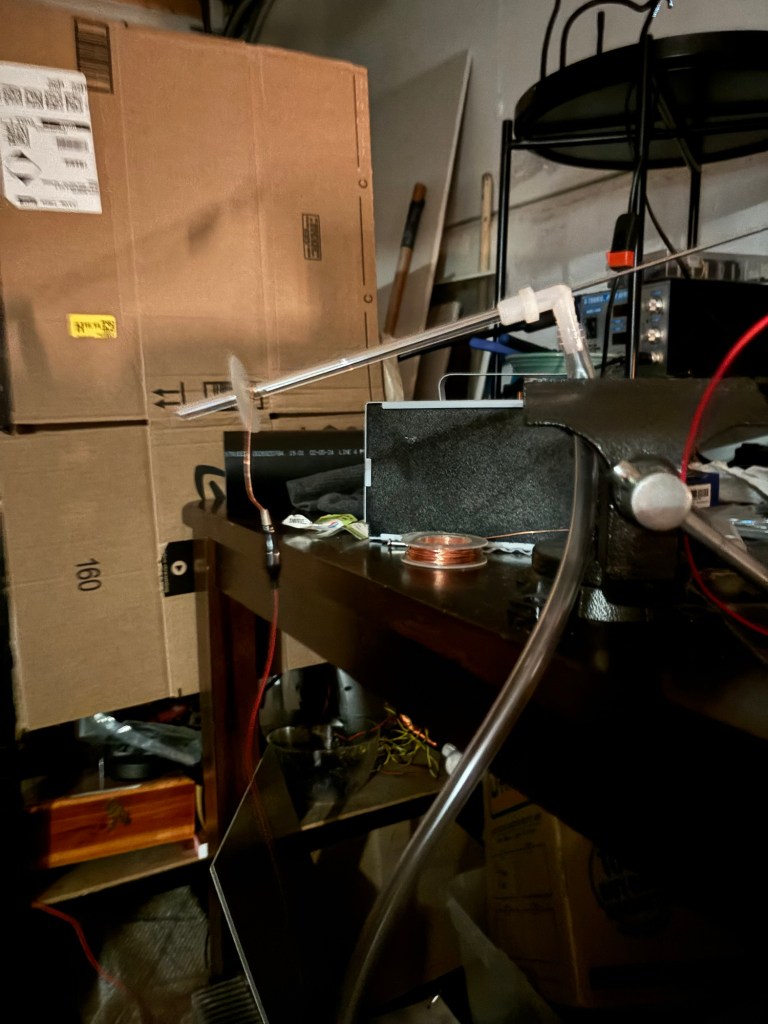

The needle is held in place by a clamp, The power supply box makes the wiring look much cleaner and adds more electrical isolation between the ground and the flyback output.

You can see that the flint glass at this thickness didn’t have a high enough holdoff and broke down. There was considerable current after breakdown which melted the flint glass (ionizing the sodium found within the glass causes the yellow light emission).

Below is a closeup of the damage. The smoke came from burning the hot glue disk.

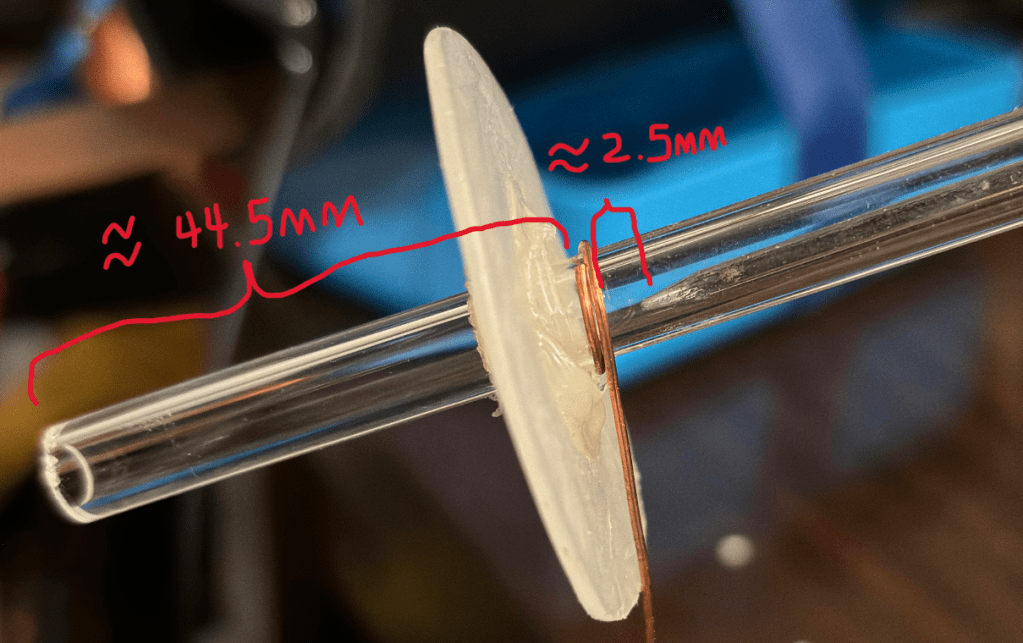

2.5mm distance from center of cathode ring to coaxial anode.

44.5mm Distance from cathode to end of tube. I later added more effective surface area from adding more glue disks.

46mm from ring-anode to end of quartz tube (not including surface area from hot glue disk).

The needle works great except for a lot of coronal discharge. Improving the hot glue disks and insulating the anode wire

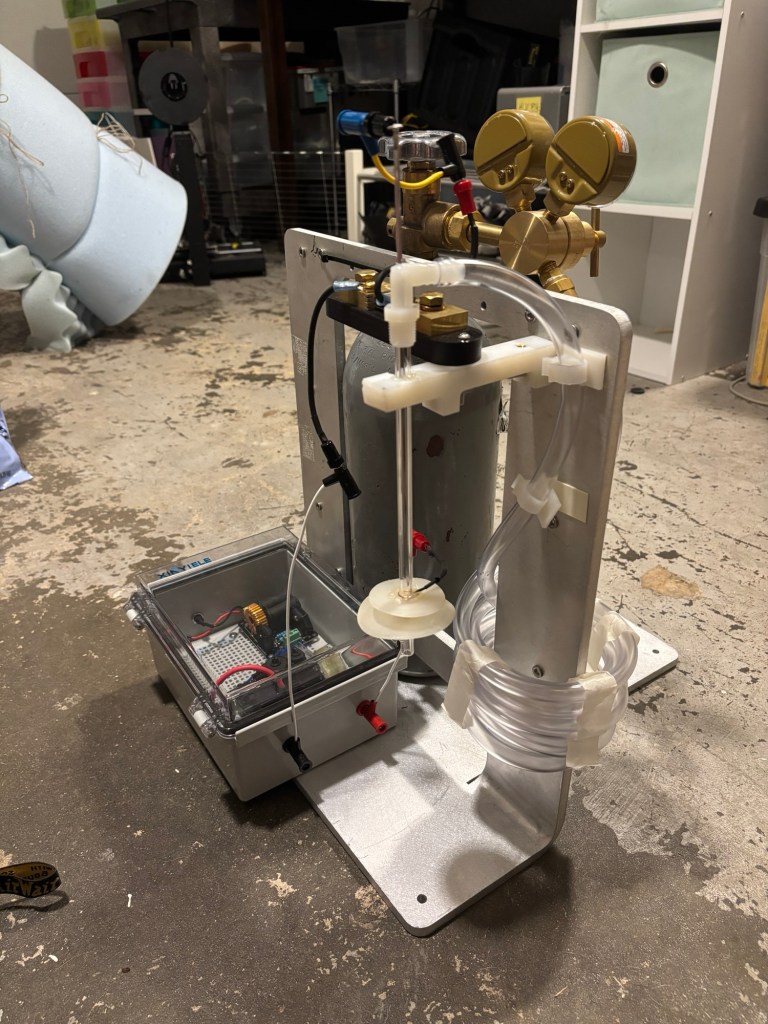

Plasma Needle 2.1 (Benchtop version)

View from front:

Note that the coil of tubing caused problems with airflow and was cut short (you might be able to see it in the demo video below).

View from back:

argon tank visible

View from top: Current viewing resistor (CVR) is visible.

I’m satisfied with the assembly for now. The next step is to use this bench for testing it’s effects on the germination rate of various plant seeds.

Leave a comment