Swamp coolers are essential in Albuquerque during the summer. They function by keeping a wet sponge that a water pump drips water over, and then a fan pulls hot air through the wet sponge. The water absorbs heat from the air, and the resulting cool air is pushed down a duct into the house.

Swamp coolers are housed in an iron box. The water system leaves a pool that sits around waiting to be pumped though that sponge I mentioned earlier. By placing a more reactive metal like a zinc or magnesium rod in the reservoir, the less reactive iron is protected as the sacrificial anode takes all the oxidation.

I only tell you this because it’s fun to know why hardware stores sell magnesium rods. Taking one of these Mg rods and some sulfur from the fertilizer section of home depot, you can make a semiconductor like they were made before silicon.

A copper wire was heated and then dipped into a sulfur powder to create CuS, which has a high carrying capacity and is resistant to oxidation (make sure to use ventilation if trying this yourself as it will make some sulfur vapor). If I use this rectifier for a power supply, I want to avoid oxidation.

Here’s a close-up of the junction between the CuS and Mg anode.

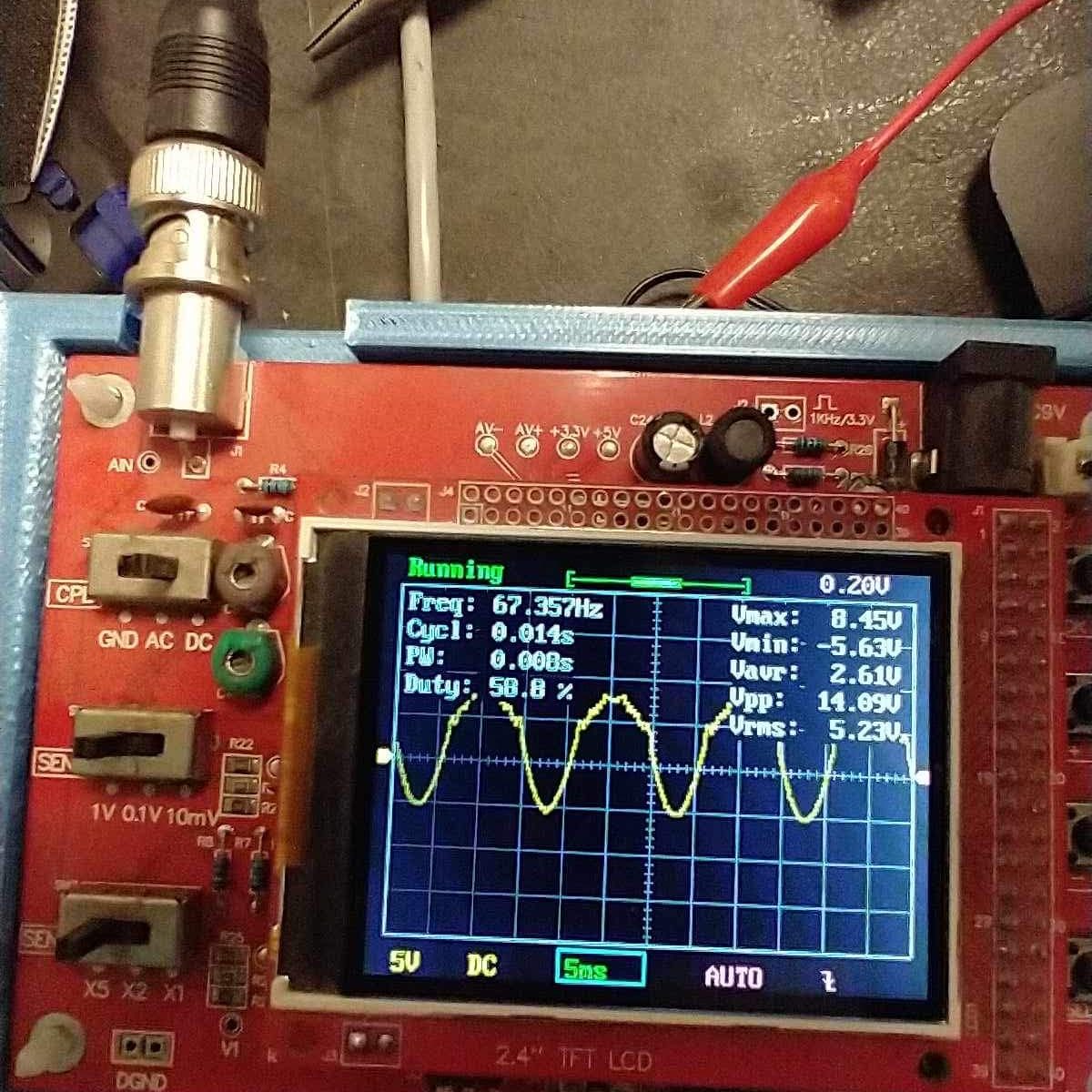

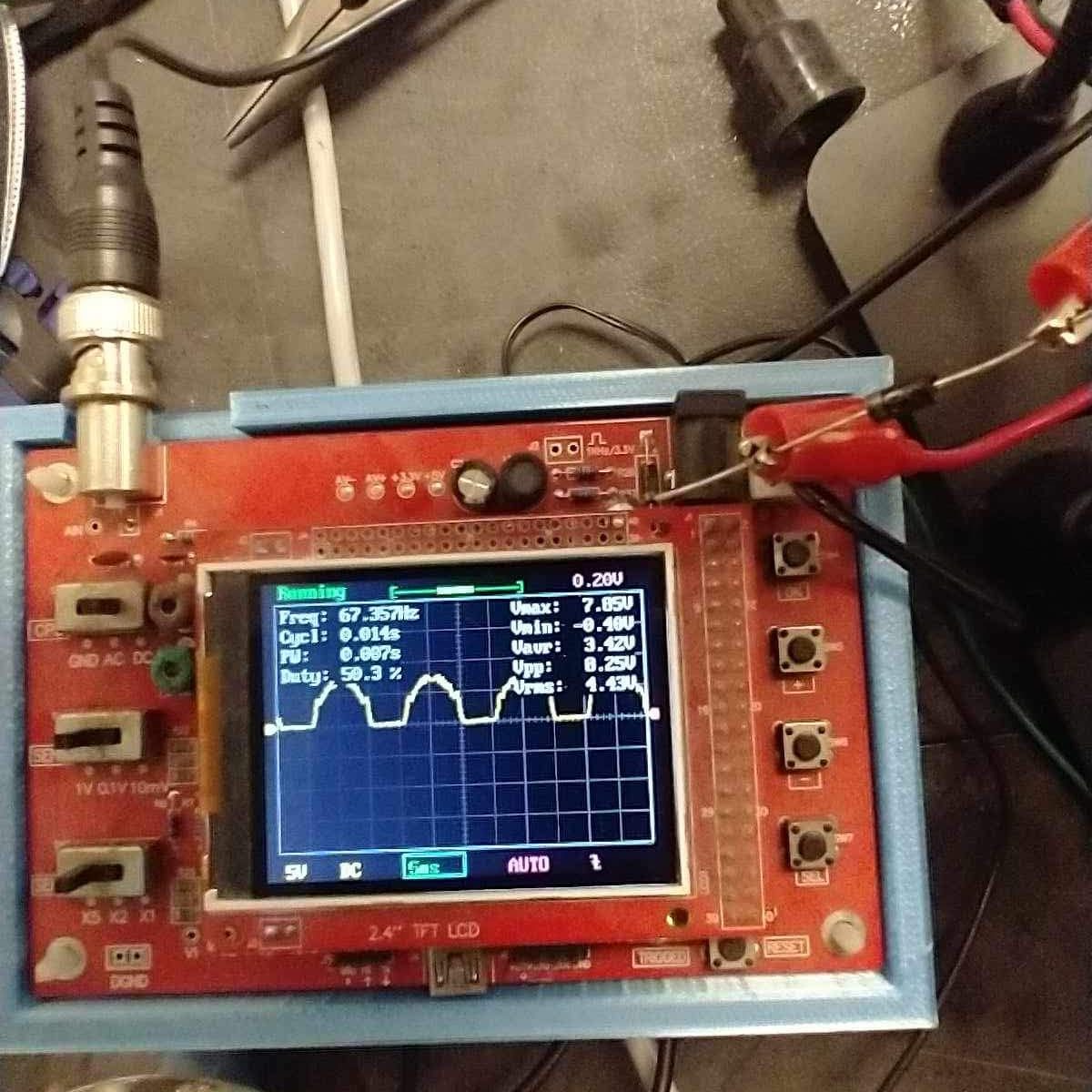

Input signal: 67.35Hz, 8.45Vmax

Open circuit voltage of function generator

Output signal: 67.49Hz, 8.05Vmax

0.4V drop across DIY metal rectifier

Open circuit voltage from Connecting the metal rectifier in series with function generator.

Output signal: 67.35Hz, 7.85Vmax

0.6V drop across commercial Silicon diode

Open circuit voltage from Connecting a commercial silicon rectifier diode in series with function generator.

The homemade CuS-Mg junction diode had a lower voltage drop then the silicon diode. Unfortunately I never measured a voltage or current rating as I moved to Seattle and dropped the project. If I revisit homebrew semiconductors I will make sure to take these measurements.

Leave a comment